Our progress on the road to 2050:

We are on track!

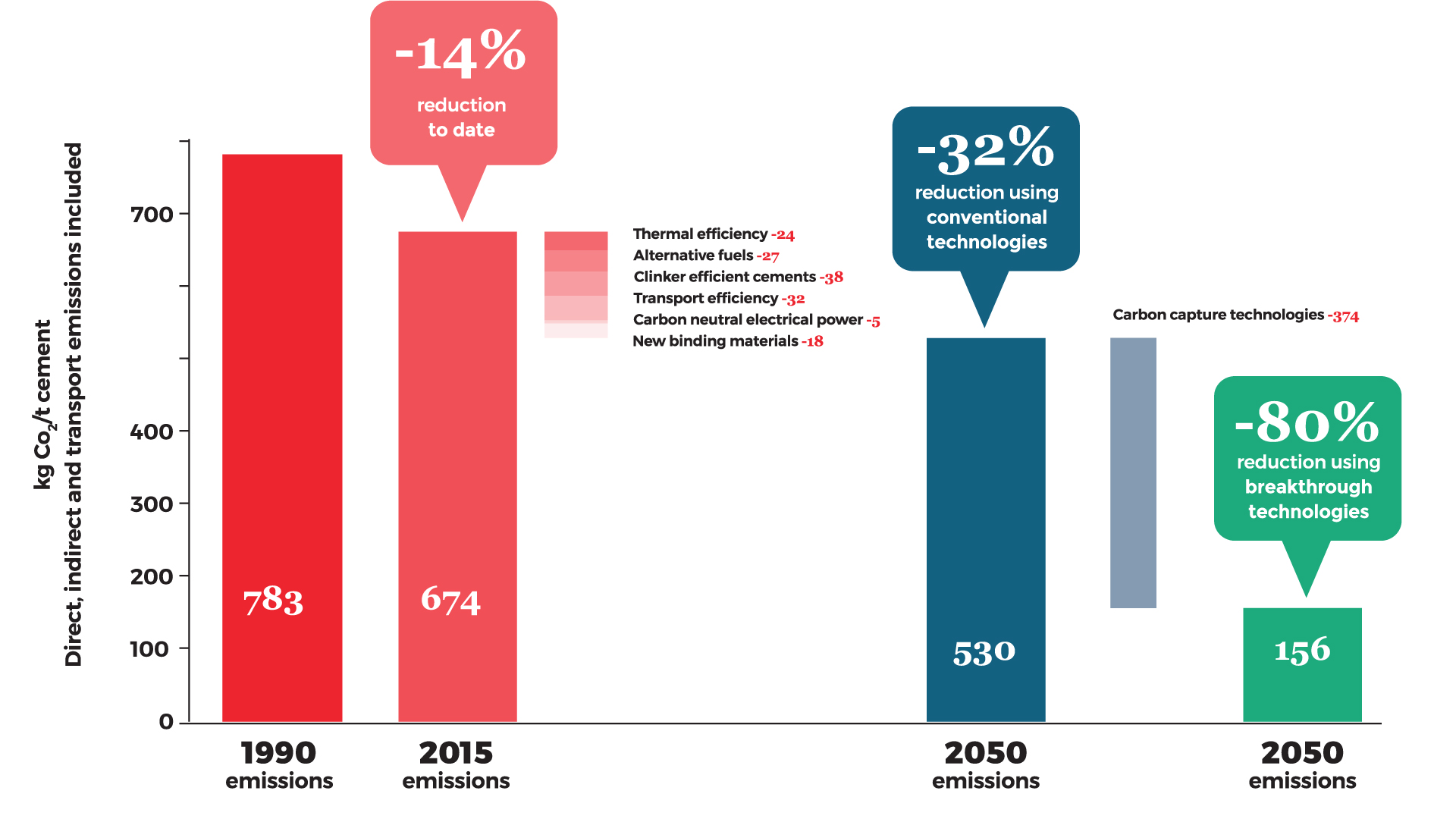

In cooperation with the European Cement Research Academy (ECRA), CEMBUREAU performed an assessment of where the European cement industry stands on its way to achieving its 2050 targets assuming that the same amount of cement will be manufactured in 2050 as in 1990. The assessment is based on 2015 data (“Getting the Numbers Right” (GNR) database) and the progress was evaluated for the specific technologies identified in the 2013 CEMBUREAU Low Carbon Roadmap.

The graph describes the technology-specific reduction potentials over three time periods:

1. 1990-2015: what has been achieved (based on GNR 2015);

2. 2015-2030 and 2030-2050: linear projection of remaining reduction potentials;

3. 2030-2050: breakthrough technologies applied.

Source: ECRA and CEMBUREAU own calculations

Note: Other technologies (e.g. electrical efficiency, alternative raw materials) not displayed as long term reduction potentials are severely limited

Source: ECRA and CEMBUREAU own calculations

Note: Other technologies (e.g. electrical efficiency, alternative raw materials) not displayed as long term reduction potentials are severely limited

Overall progress towards the 2050 target set in the 2013 CEMBUREAU Low Carbon Roadmap

2050 TARGET |

ASSESSMENT (on the basis of 2015 data) |

|---|---|

|

32% CO2 emission reduction using conventional technologies |

Close to 14% emission reduction to date, with substantial progress achieved in thermal efficiency and alternative fuels.

More details, including on novel cements, are outlined in the accompanying clinker and cement progress sections. |

|

80% CO2 emission reduction using breakthrough technologies |

Several breakthrough technologies such as carbon capture and storage, and reuse (CCS/CCU) are under development. Technology is now available at demonstration scale and the cement industry is involved in several promising research projects. With the right co-financing framework, it is expected that these technologies will become commercially available after 2030. Education and training of the value chain will be necessary before these technologies will become widespread and commercially viable. Some technologies are at a more advanced stage, but rely on a shift in market acceptance and demand. These could benefit from an increased legislative focus on demand-pull policies as well as standards and building codes providing the necessary quality assurance. |

Alignment with the 2°C Scenario of the Paris Agreement

Science Based Targets Assessed

CEMBUREAU has asked PwC (PricewaterhouseCoopers) to assess the extent to which the greenhouse gas (GHG) emission reduction targets set for the European cement industry are sufficient to meet the temperature goals adopted in the Paris Agreement, i.e. limit global temperature rise this century to well below 2°C.

Responding to CEMBUREAU’s request, PwC has applied an empirical approach using several established Science Based Target (SBT) methodologies in order to compare their outcomes with the targets set in the CEMBUREAU Low Carbon Roadmap.

The preliminary assessment indicates that the CEMBUREAU Roadmap is compliant with a number of SBT methodologies in its 2050 perspective and is therefore a robust instrument to guide the cement sector towards achieving the Paris Agreement objectives.

more ambitious

than the global scenarios

The European cement industry has taken an active role in the development of the International Energy Agency’s (IEA) “Technology Roadmap for Low Carbon Transition in the Cement Industry” in partnership with the World Business Council on Sustainable Development (WBCSD), the Cement Sustainability Initiative (CSI). In 2009, the first sectoral low carbon technology roadmap for the cement industry was published, identifying the existing and upcoming technological levers to mitigate CO2 emissions from the sector and paving the way for other sectors to follow. In 2018, the cement industry was the first sector to have its original technology roadmap updated, integrating new technologies.

Our assessment shows that the 2013 CEMBUREAU Low Carbon Roadmap is more ambitious than the 2018 IEA scenarios, in particular when it comes to fuel substitution and breakthrough technologies. Clinker substitution for the European region remains a challenge.

Because of Europe’s decarbonisation agenda, there is lower availability of clinker substitutes, such as slag from the steel sector and fly ash from the power sector, compared to other regions of the world. More importantly, differences in cement qualities, stemming from varying requirements for performance and durability of construction across the world, make a direct comparison of clinker-to-cement ratio in different regions of the world challenging.

Looking from the entire construction value chain’s perspective, cement quality and performance in concrete are also a complicating factor in comparing clinker-to-cement ratios at a global scale.