The story of cement manufacture

Before entering into the detail of each of the five parallel routes, it is essential to provide more background on the industrial context in which these reductions are suggested. In the chapters below, more information is provided on the characteristics of cement, its production process and use and where the sector is now in terms of emission reductions already achieved.

WHAT IS CEMENT?

Cement is a fine, soft, powdery-type substance, mainly used to bind fine sand and coarse aggregates together in concrete. Cement is a glue, acting as a hydraulic binder, i.e. it hardens when water is added. Everyone knows the word cement, but it is often confused with concrete or mortar. Cement is a key ingredient in both concrete and mortar, and it is always mixed with other materials before use:

- Cement mixed with water, sand and gravel forms concrete, which is what the vast majority of cement is used for.

- Cement mixed with water, lime and sand forms mortar.

Cement and concrete have been used to build durable structures for quite some time. The Coliseum in Rome, completed in 80 AD, is a good example of how a concrete structure can withstand time. The cement used by the Romans was produced using locally available raw materials, chalk and volcanic ash heated in open fires. The modern version of cement, called Portland cement, was developed back in the early 19th century and has been improved ever since.

There are 27 types of common cements that can be grouped into five general categories (CEM I Portland cement, CEM II Portland-composite cement, CEM III Blastfurnace cement, CEM IV Pozzolanic cement, and CEM V Composite cement) and three strength classes: ordinary, high and very high. The standard for common cements further specifies 7 sulfate resisting common cements, 3 distinct low early-strength blast furnace cements and 2 sulfate resisting low early strength blast furnace cements. There are also a number of special cements, such as super sulfate-cement, very low-heat cement and calcium aluminate cement.

WHAT IS CONCRETE?

Concrete is a mixture of cement, water Aggregates and in some cases a small amount of ingredients called admixtures. Aggregates make up approximately 60-75% of the mixture and cement and water make up the rest. Aggregates are usually inert coarse materials like gravel, crushed stone, sand or recycled concrete. The type of aggregate selected depends on the application of the concrete. Thanks to the special binding properties of cement, concrete is a very resilient, durable material that can bear heavy loads and resist environmental extremes.

CEMENT & CONCRETE

The vast majority of cement is used to make concrete. For this reason, any roadmap must also take into account the final product, i.e. concrete. This is especially relevant because as more new cement types are developed, the amount of cement needed to make concrete could vary.

An efficient use of cement products and concrete and the end-of-life aspects of these products have a direct impact on the sustainability of concrete. This roadmap will therefore also look into innovative construction methods that will allow reuse of concrete building elements and components.

CEMENT MANUFACTURE

The cement-making process can be divided into two basic steps:

- Clinker (the main constituent of cement) is first made in a kiln with gas up to 2000°C, which heats raw materials such as limestone (calcium carbonate) with small quantities of other materials (e.g. clay) to 1,450°C. During this process, known as calcination, the calcium carbonate (limestone) is transformed into calcium oxide (lime), which then reacts with the other constituents from the raw material to form new minerals, collectively called clinker. This near-molten material is rapidly cooled to a temperature of 100 – 200°C.

- Clinker is then ground with gypsum and other materials to produce the grey powder known as cement.

Clinker production

QUARRYING RAW MATERIALS

Cement plants are typically located close to naturally occurring materials like limestone, marl or chalk, which are extracted from quarries, providing calcium carbonate (CaCO3). Very small amounts of materials such as iron ore, bauxite, shale, clay or sand may be needed to provide the extra mineral ingredients, iron oxide (Fe2O3), alumina (Al2O3) and silica (SiO2) necessary to produce the desired clinker.

CRUSHING

Raw material is quarried and transported to primary/secondary crushers and broken into 10cm pieces.

RAW MEAL GRINDING

After crushing, the raw materials are mixed and milled together to produce ‘raw meal’. To ensure high cement quality, the chemistry of the raw materials and the subsequent raw meal is very carefully monitored and controlled.

PREHEATING

Hot exhaust gases coming from the kiln preheat the powdered raw meal before it enters the kiln. A preheater consists of a series of cyclones through which the raw meal is passed by swirling hot flue gases in the opposite direction of the material flow. In these cyclones, thermal energy (heat) is recovered from hot flue gases with the benefits that the raw meal is preheated, the efficiency of the process is improved and less fuel is needed. Depending on the raw material moisture content and heat recovery requirements, a kiln may have up to six stages of cyclones, with increasing heat recovery at each extra stage.

PRECALCINING

Calcination is the transformation of limestone into lime. Part of the high temperature reaction in modern installations takes place in a ‘precalciner’, a combustion chamber at the bottom of the preheater above the kiln, and partly in the kiln. Here, the chemical decomposition of limestone, generating typically 60% of total CO2 emissions of the cement manufacturing process occurs. Fuel combustion generates the rest of the CO2.

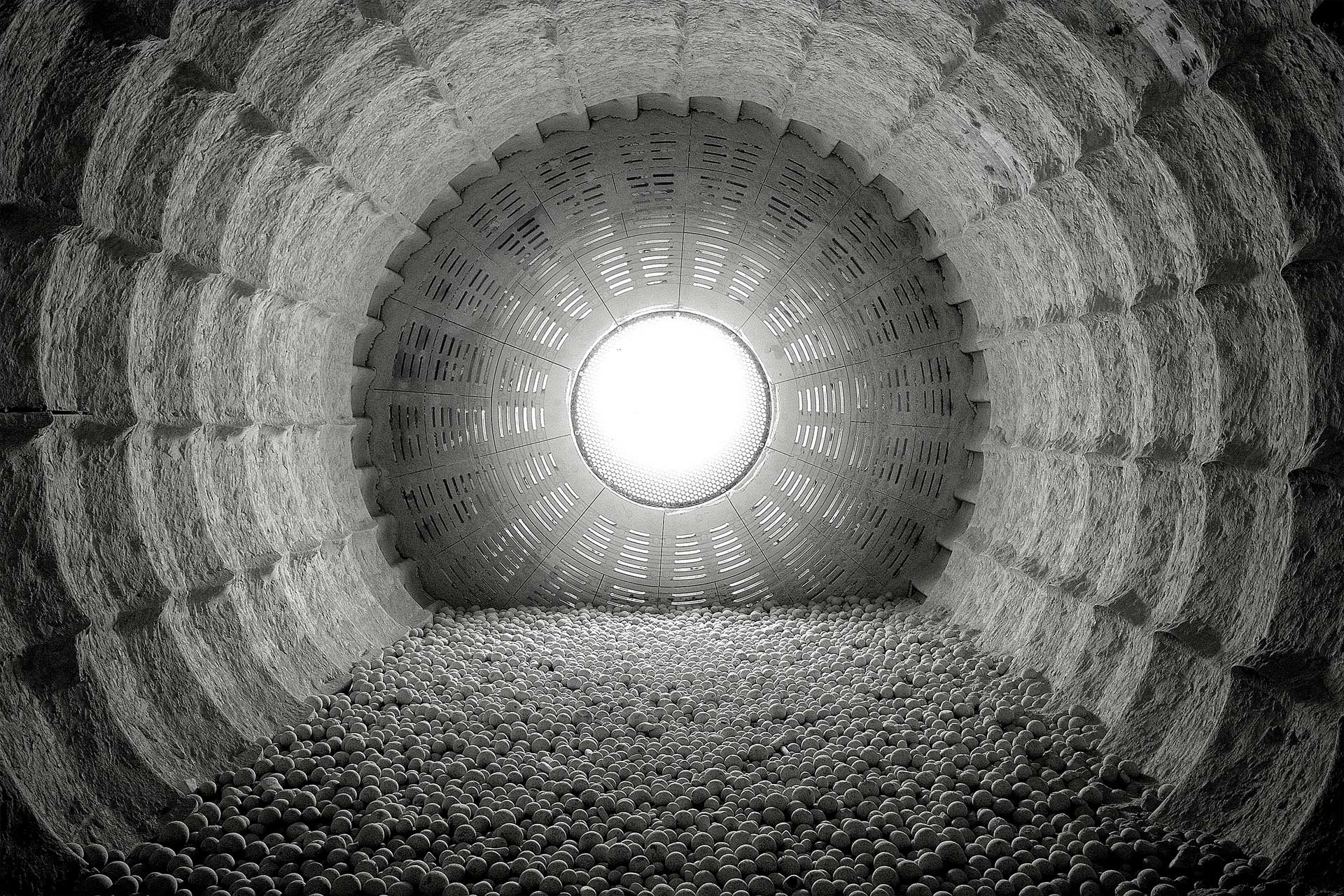

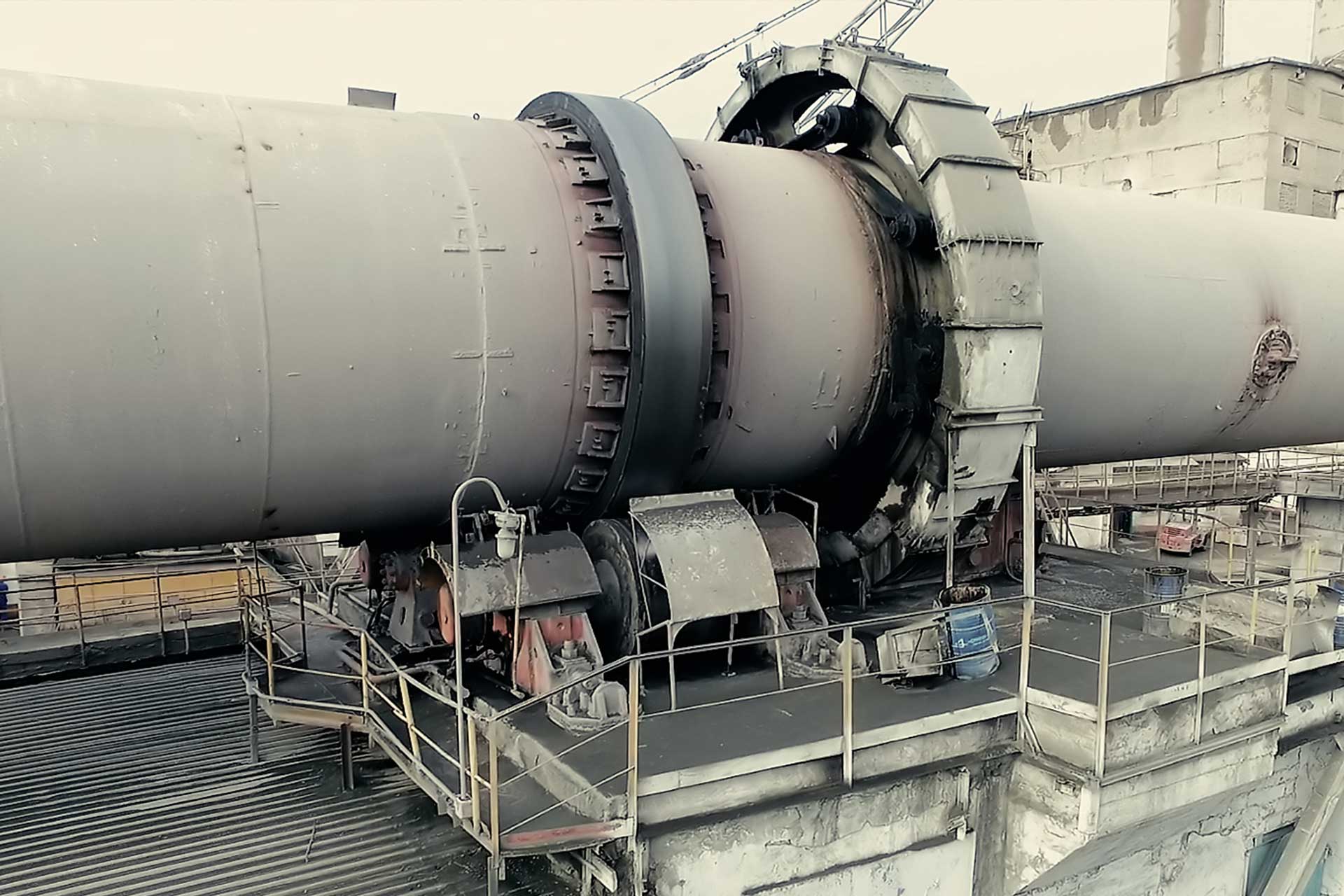

CLINKER PRODUCTION IN THE ROTARY KILN

Precalcined meal then enters the kiln at temperatures of around 1000°C. Fuel (such as coal, petroleum coke, gas, oil and alternative fuels) is fired directly into the rotary kiln at up to 2000°C to ensure that the raw materials reach material temperatures of up to 1,450°C. The kiln (a brick-lined metal tube 3-5 metres wide and 30-60 metres long) rotates about 3-5 times per minute, and the raw material flows down through progressively hotter zones of the kiln towards the flame. The intense heat causes chemical and physical reactions that partially melt the meal into clinker. There are older, much less efficient technologies, for example wet kilns into which raw material is fed as wet slurry and not as powder (as is the case in dry kilns). However, wet kilns have almost been phased out and today over 90% of European cement clinker is produced in dry kilns.

COOLING AND STORING

From the kiln, the hot clinker is cooled using large quantities of air, part of which can serve as combustion air. Coolers are essential for the creation of the clinker minerals which define the performance of the cement. In this process, the combustion air is preheated, thereby minimising overall energy loss from the system. Clinker is usually used on site but can be transported by truck, train or ship to other grinding plants.

CEMENT GRINDING

Around 4-5% gypsum is added to clinker to control the setting time of the final cement. The cooled clinker and gypsum mixture is ground into a grey powder called Ordinary Portland Cement (OPC), or can be ground with other mineral components to produce, for example, Portland Composite Cements (PCC). Traditionally, ball mills have been used for grinding, although more efficient technologies like roller presses and vertical mills or combinations thereof are used in many modern plants today.

BLENDING

Cement may also be mixed with other finely ground mineral components, such as considerable amounts of slag, fly ash, limestone or other materials to replace part of the clinker, thereby often achieving a significant reduction of the CO2 emissions.

STORING IN CEMENT SILOS

The final product is homogenised and stored in cement silos and then dispatched to either a packing station (for bagged cement) or to a silo for transport by water, road or rail.