A low-carbon European concrete and cement sector in 2050

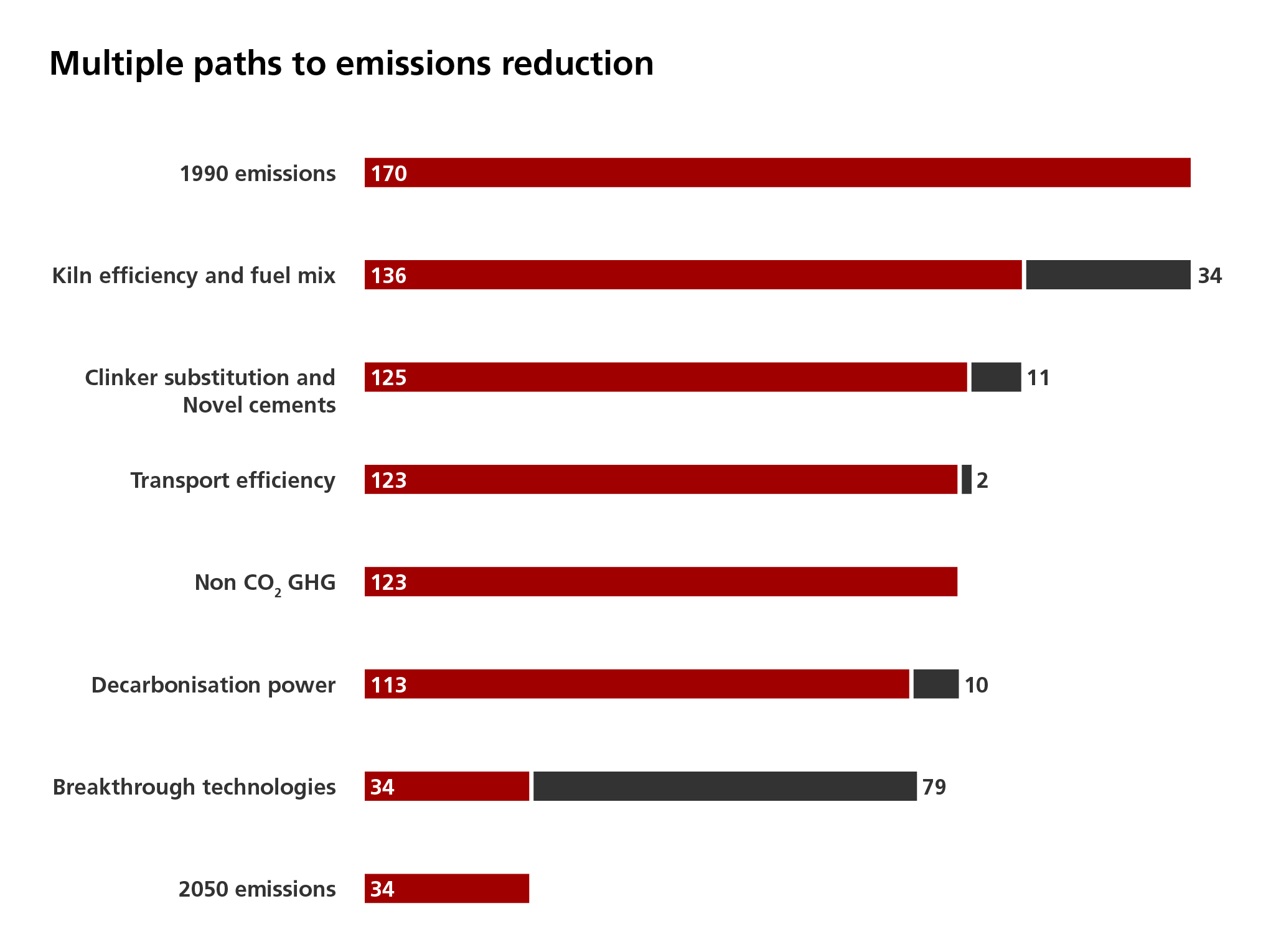

This document presents a vision for the sector whereby the cement carbon footprint could be reduced by 32% compared with 1990 levels, using mostly conventional means. It also describes potential levers for how this could be further increased by the application of emerging new technologies, such as carbon capture and storage (CCS). Subject to specified policies and technological prerequisites, a potential reduction of up to 80% may be envisaged.

The industry has focused on five routes to achieve these objectives, three of which are considered to be ‘under the sector’s control’. Potential savings from the other two routes outlined (Product Efficiency and Downstream) do not relate directly to cement manufacturing, so were not included. The sector is committed, however, to investing in innovation that explores new ways for cement and concrete to contribute to a low carbon and circular economy, especially where life cycle emissions of buildings and structures can be meaningfully reduced by intelligent use of concrete. This could increase the overall contribution further.

RESOURCE EFFICIENCY |

ENERGY EFFICIENCY |

CARBON SEQUESTRATION AND REUSE |

PRODUCT EFFICIENCY |

DOWNSTREAM |

There is no single choice or technology that will lead to an 80% reduction in emissions. Only a combination of different ways to reduce emissions, as set out in each of the chapters below, can achieve substantial reductions.

The contribution of each of the levers to the overall reduction is summarised in the graphs to the right.

BUILDING BLOCKS AND ASSUMPTIONS

In order to calculate potential savings, we made a series of assumptions on:

We do not know how much cement will be produced in Europe by 2050. For the numbers to be meaningful, we assumed that the same amount of cement will be manufactured in 2050 as in 1990.” button_url_new_window=”1″ use_icon_font_size=”on” back_color=”#f6f6f6″ image_alignment=”center” front_horizontal_align=”center” back_horizontal_align=”left” _builder_version=”3.15″ header_front_level=”h1″ header_front_font=”||||||||” header_front_text_align=”center” header_front_text_color=”#ffffff” header_front_line_height=”1.3em” body_font=”||||||||” body_text_align=”center” body_text_color=”#ffffff” header_back_level=”h1″ header_back_font=”||||||||” header_back_line_height=”1.3em” body_back_font=”||||||||” background_color=”#e00000″ text_orientation=”left” custom_padding=”20px|20px|20px|20px” /]