Clinker Substitution

IN BRIEF

- Clinker can be blended with a range of alternative materials, including pozzolans, finely ground limestone and waste materials or industrial by-products. The clinker-to-cement ratio (percentage of clinker compared to other non-clinker components) has an impact on the properties of cement so standards determine the type and proportion of alternative main constituents that can be used.

- To ensure the future use of other constituents, the cement industry is dependent on the local supply of these materials.

The use of other constituents in cement and the reduction of the clinker-to-cement ratio means lower emissions and lower energy use. Ordinary Portland cement can contain up to 95% clinker (the other 5% being gypsum). The current average clinker-to-cement ratio over all cement types in the EU27 is 73.7%1.

Different cement types have different properties, including hardening time, early and late strength, resistance to salty conditions and chemically aggressive environments, heat release during curing, colour, viscosity and workability. The importance and relevance of these qualities depend on the desired application of the cement and concrete.

There is a need to ensure that all the cement manufactured is safe and durable as it will be used in structures that are made to last at least 50 years or more. Thus, high durability of the final product concrete is a key property for sustainable construction. Cement in Europe must be manufactured according to the harmonised European Standard EN 197-1, which lists 27 common cements according to their main constituents. The theoretical clinker content of these cements in the European Standard can vary between 5% and 95%. Varying clinker content has an impact on the type of applications the cement can be used for.

Other materials that can be used

- Natural pozzolans, such as clays, shale and certain types of sedimentary rocks.

- Limestone (finely ground), which can be added to clinker (without being heated and transformed into lime).

- Silica fume, a pozzolanic material and a by-product in the production of silicon or ferrosilicon alloys.

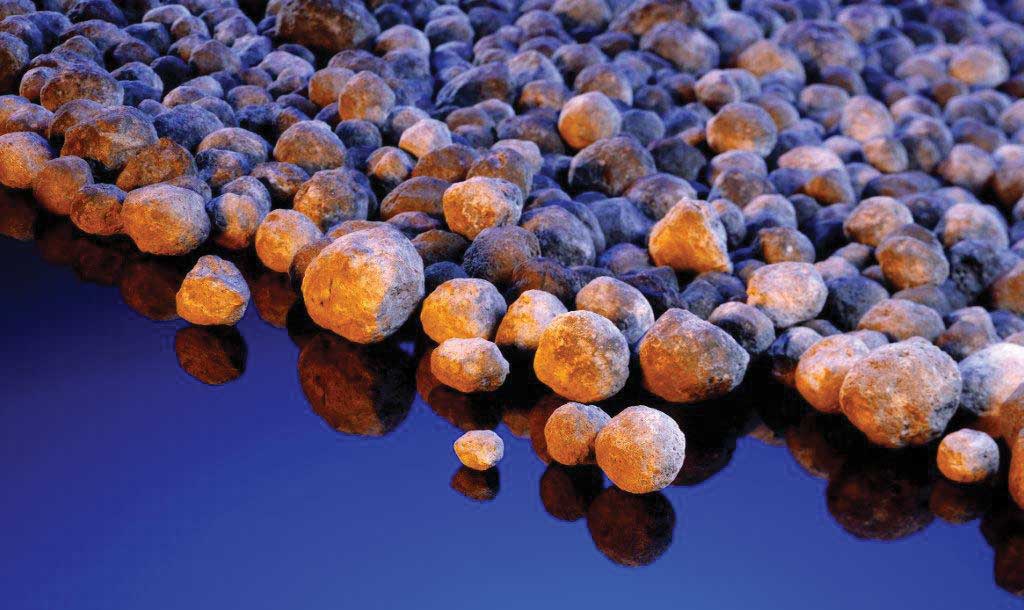

- Granulated blastfurnace slag (GBFS), a by-product of the pig-iron/steel production process.

- Fly ash, dust-like particles from flue gases of coal-fired power stations.

CHALLENGES

Availability

The availability of alternative materials that can be used as other constituents varies considerably. For example, granulated blastfurnace slag availability depends on the location and output of blastfurnaces for pig-iron production equipped with slag granulation facilities, whilst fly ash use is dependent on supply from sufficiently close coal-fired power plants. The availability of pozzolans depends on the local situation and only a limited number of regions have access to this material for cement production. Limestone is abundant worldwide and is easily accessible to most cement plants.

Standards & Market acceptance

Cement standards serve to guarantee the performance of each cement type. The use of other constituents has an impact on the way the cement will perform in both the short and long term. The success of cements with a low clinker-to-cement ratio will also depend on market acceptance. Quality is crucial for building stability and, as such, a matter of public safety, e.g. bridges, sky scrapers as well as for the sustainability of investments into infrastructures and buildings.

POTENTIAL SAVINGS

A global clinker-to-cement ratio of 78% in 2006 meant that about 550-600 million tonnes of constituents other than clinker were used. The International Energy Agency (IEA)2 estimated that in 2005, there were around 1,215 million tonnes of material suitable for clinker substitution globally (excluding pozzolan and limestone). On this basis, it seems that the use of other constituents could be doubled. However, this scenario is only hypothetical because it does not take into account that these quantities do not necessarily reflect the required quality or local market situation3. There is also uncertainty regarding the future availability of clinker substitutes as well as the impact of environmental policy and regulation.

For example, the future decarbonisation of the power sector could limit the availability of fly ash, or the application of Nitrogen Oxide(s) abatement techniques in coal-fired power stations could mean that the fly ash may be unusable as a constituent in cement due to higher NH3 (ammonia) concentrations. Furthermore, some of these materials are already used in concrete, rather than cement, production. Finally, a life cycle cost analysis needs to be done to ensure that policies are based on the entire life cycle in order to avoid focusing solely on intermediate material impact.

At a European level, it is estimated that the clinker-to-cement ratio can be reduced to 70%, resulting in a further CO2 saving of 4%

POLICY RECOMMENDATIONS

- Low-clinker cements can offer both environmental benefits as well as favourable product characteristics. Nevertheless, it is important that a whole life cycle approach is applied to public procurement rather than simply focusing on product footprinting or intermediate product impacts.

- Facilitate access to raw materials and enhancing waste and by-products recycling policies.

- Provide support for and access to R&D funding. In addition, a strong industry focus on innovative cements and concretes has the potential to respond to the requirements of sustainable and resource-efficient production and construction.

1 For the purposes of meaningful reporting, the definition of cement used in the GNR database differs slightly from that in common use. In this document, cement and cementitious products are considered equivalent.

2 Source: http://www.wbcsdcement.org/pdf/technology/Technology%20papers.pdf

3 Source: Development of State of the Art Techniques in Cement Manufacturing: Trying to Look Ahead (CSI/ECRA- Technology Papers), State of the Art Paper No 4: Reduction of clinker content in cement: long-term perspective