Our 2050 Roadmap: The 5C Approach

Clinker

As recognised in the European Green Deal, the circular economy goes hand in hand with carbon neutrality. Circularity is crucial to reduce emissions from clinker, which is the backbone of cement production. Already today, nonrecyclable waste is used to phase-out fossil fuels from cement production. It will become even more crucial tomorrow, as CO2 captured during clinker manufacturing will be used in other industrial applications.

Clinker is produced by heating crushed limestone and a mix of other materials (clay and sand) to 1450 °C in a rotary kiln. Clinker is later ground down to a fine powder and mixed with gypsum and other ingredients to make cement. The rotary kiln is the heart of the manufacturing process where raw materials are heated up and decarbonisation of the limestone takes place through a chemical reaction referred to as calcination.

It is this chemical process which causes 60%-65% of cement manufacturing emissions (process emissions).

The remainder of CO2 emissions comes from the fuels used to heat the kiln (combustion emissions). Since clinker production represents the lion share of emissions, this is obviously the area that offers most opportunities for deeper CO2 emission cuts.

Opportunities to Achieve CO2 Reductions for Clinker

How can we reduce emissions from clinker?

Alternative Decarbonated Raw Materials

As the largest source of CO2 comes from calcining the raw materials in the kiln, the use of alternative sources of decarbonated materials is one option for significantly reducing CO2 emissions. Waste materials and by-products from other industries can be used to replace some of the limestone, a good example of industrial symbiosis. These materials can include recycled cement paste from demolition waste, air-cooled slag and waste lime. A study will be conducted by CEMBUREAU to determine potential sources of alternative waste raw materials and clinker replacement materials from different industries.

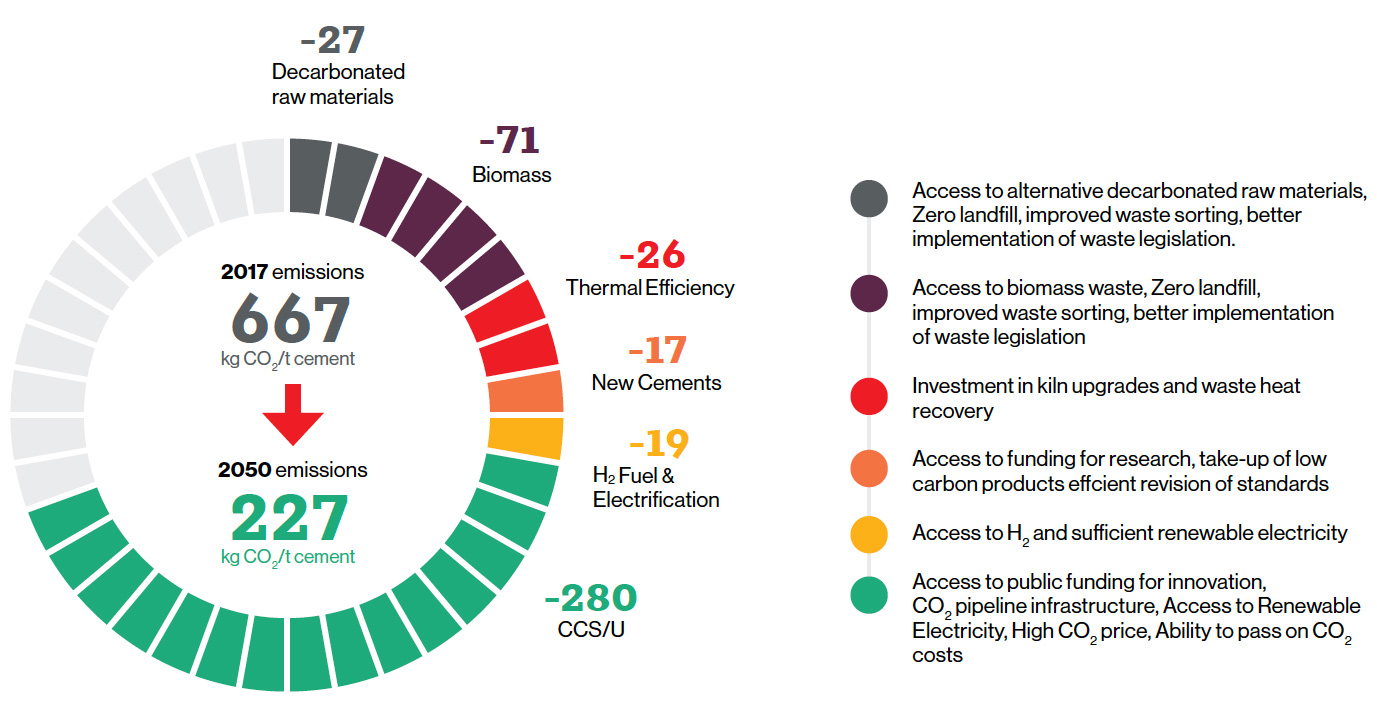

CEMBUREAU envisages up to a 3.5% reduction of process CO2 using decarbonated materials by 2030 and up to 8% reduction by 2050.

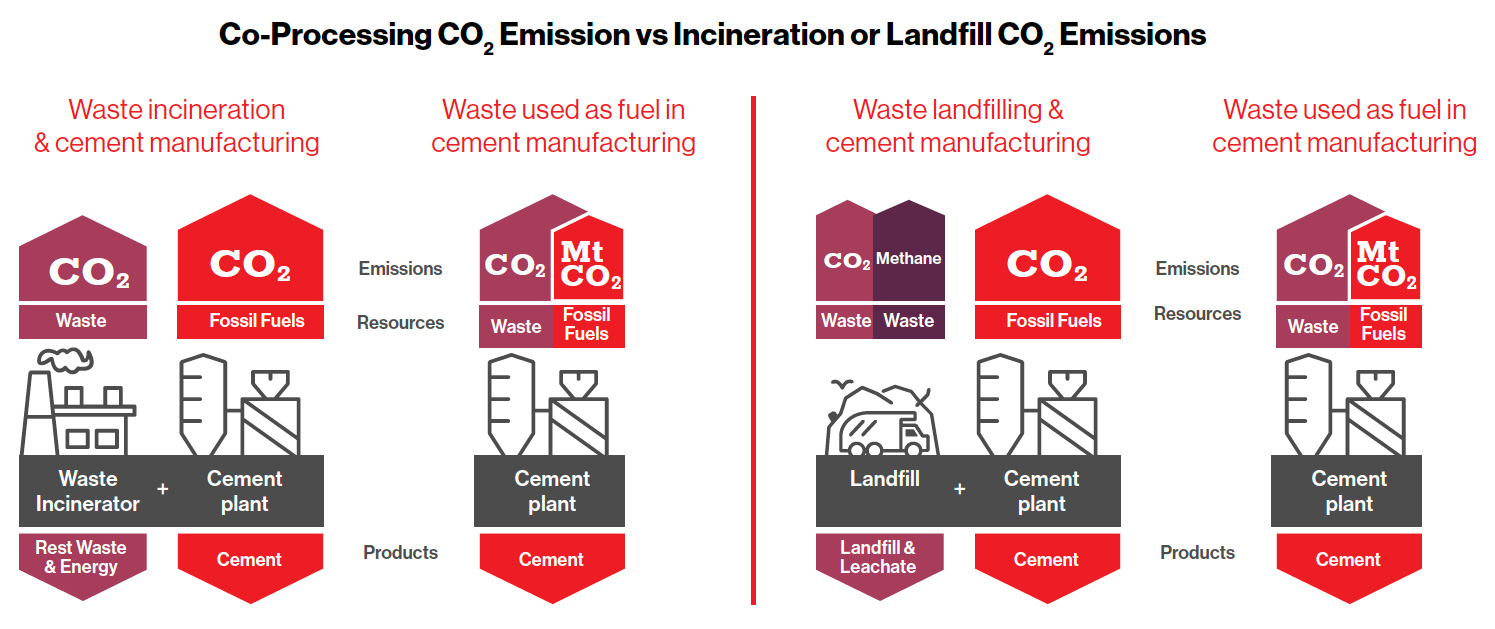

Fuel Substitution and Zero Fuel Emissions Research

Fuel emissions account for approximately 35% to 40% of total CO2 emissions from cement manufacturing. In producing cement we simultaneously recover energy and recycle minerals from a variety of waste streams (Co-processing) and use biomass. Co-processing puts the cement industry at the heart of the circular economy, and plays a key role in terms of waste management in local areas and municipalities. CO2 is saved by replacing fossil fuels with the alternative waste streams, but also through those emissions not being made through incineration or through methane emissions from landfill. Refer to figures below.

In 2017, alternative fuel use represented 46% of the total fuel needs of kilns across Europe of which 16% was biomass.

There are no technical impediments to increase the use of alternative fuels to over 90% if the materials are locally available. In fact, several plants do achieve that level thanks to the correct regulatory environment, public acceptance and investment support.

Examples are Allmendingen, Germany operated by Schwenk Cement and Retznei, Austria operated by LafargeHolcim which both use up to 100% alternative fuels and 12% alternative raw materials and Brevik, Norway operated by HeidelbergCement, which uses 72% alternative fuels.

In addition, research is ongoing, although it is at an early stage to use electrical heating, plasma or solar energy to calcine the raw materials which could in the future result in saving 55% of the fuel CO2 if renewable electricity is used. Combined with the use of hydrogen and biomass fuels for the clinker process, this could result in near zero fuel CO2 emissions.

CEMBUREAU targets to reach 60% alternative fuels containing 30% biomass in 2030, and 90% alternative fuels with 50% biomass by 2050.

New types of Cement Clinkers and the use of Mineralisers

New types of cement clinkers are being developed that are chemically different from conventional Portland cement clinker. These result in 20 – 30% CO2 savings by reducing the amount of limestone in the formulation and because they require less energy. It should be noted, however, that because these cements have different properties, they can only be used for specific applications. Examples of these include Sulpho-Aluminate Clinker (SAC), Ferro-Aluminate Clinker (FAC), Belite-Ye’elimite-Ferrite Clinker, Calcium Aluminate Clinker and Amorphous Clinker (X-Clinker).

CEMBUREAU has targeted a 2% reduction in process CO2 emissions by 2030 and 5% by 2050. These numbers consider limits in application of some of these cements and the time needed for market acceptance.

Thermal Efficiency

Cement kilns are already efficient, typically operating at levels between 70 to 80% efficiency1. However, improvements can still be made to the thermal efficiency of some of our kilns through converting preheater and other kiln types to precalciner kilns and by recovering heat from the cooler to generate up to 20% of electricity needs for the cement plant.

CEMBUREAU is targeting a 4% improvement in thermal efficiency by 2030, moving to 14% in 2050.

Carbon Capture, Utilisation and Storage (CCUS)

Last but not least, CCUS will be a key technology to reduce CO2 emissions from cement plants. In recent years, significant research has been undertaken at a pilot scale level to optimise reagent and membrane capture techniques. Trials are underway to find ways of concentrating the CO2 in the gas stream as to make the carbon capture more efficient and cost-effective (refer to the Cleanker and Catch4climate projects below). Captured CO2 can then be transported to geological formations (such as empty gas fields), where it is permanently stored (example: Brevik plant in Norway, operated by Heidelberg Cement). Other permanent CO2 capture techniques include the use of recycled concrete aggregates and minerals (such as olivine and basalt). Algae can also be used to absorb CO2 and grow biomass, which can later be used to fuel the kiln, refer to the CIMENTALGUE project below.

The captured CO2 can also be used to create new products such as carbon neutral aviation fuel (refer to the WestKuste 100 below).

Whilst there are plans aiming for full scale implementation of CCUS, its development will largely depend on the development of a CO2 pipeline infrastructure, as well as the development of an overall business case. The development of appropriate policies will play a key role in this respect. A study will be conducted by CEMBUREAU to identify the potential carbon storage sites in relation to the location of cement works in the EU and to determine which of the existing pipelines should be allocated for CO2 transport.

By 2050 the total use of the different carbon capture techniques will reduce CO2 emissions by 42%.

[1] “Evaluation of energy performance in cement kilns in the context of co-processing, European Cement Research Academy, 2016.”

How can policy support this transformation?

Reducing clinker emissions will necessitate considerable investments in low-carbon technologies. As highlighted earlier, creating a favourable framework for these investments to happen – through a level playing field on carbon, appropriate funding for research, and a longterm vision – will be critical.

EU policy will also play a pivotal role in reducing clinker emissions through two policies that are at the core of the Green Deal: circular economy and the development of lead technologies for decarbonisation such as CCUS.

We will require more access to non-recyclable waste and biomass waste to phase out the use of fossil fuels. Policies should facilitate waste shipment between EU countries, discourage landfill and prohibit exports of waste outside of the EU. In addition, sufficient access to biomass and non-recyclable waste should be guaranteed for co-processing in cement kilns, as the most ecological solution for the majority of materials.

Energy-intensive industries, including cement, will need sufficient infrastructure to transport, re-use and store the CO2 it captures. The EU should urgently look at developing a pan-European CO2 transportation network that responds to the industry’s needs. Continued support for CCUS technologies, as well as measures to support the business case of this technology (such as State Aid), are urgently needed.

Innovation in action

Some examples of research projects aiming to reduce CO2 emissions

CEMZero

The CEMZero project is investigating the use of electricity to heat kilns.

SOLCEMENT

This project aims at developing and evaluating an integrated system on the basis of using concentrated solar radiation for the process of limestone (CaCO3) decomposition to calcium oxide (CaO), mainly serving the needs of the cement industry.

Leilac

The Leilac project carries the calcination of raw materials in a separate vessel from the kiln through conduction producing a gas stream with over 95% CO2.

CIMENTALGUE

The CIMENTALGUE is testing the use of algae to capture CO2 from the exhaust gases in warmer climates. The algae could be used as a source of biomass fuel for the kiln.

WestKuste 100

WestKuste 100 is a joint project between several industries and the local authorities, that uses oxyfuel combustion and CO2 capture at the Largerdorf Cement Works to create green methanol.

Cleanker

Cleanker uses oxyfuel combustion (replacing air with oxygen and recycled CO2) and CO2 recycling to produce a CO2 gas stream of over 90%.

Catch4climate

An oxyfuel test facility at semi-industrial scale was installed at the premises of the cement plant in Mergelstetten, Southern Germany. This will utilize oxyfuel combustion to concentrate the CO2 stream for CCU.

Recode

This project aims to use CO2 from the flue gases of a rotary kiln in a cement industry to produce value-added chemicals (acid additives for cement formulations) and materials (CaCO3 nanoparticles to be used as concrete fillers).